When considering essential components in the hospitality and food service industry, ice might not necessarily be the first thing that comes to mind. However, ice production plays a pivotal role in various businesses, from restaurants and bars to hotels and healthcare facilities. Have you ever pondered the science behind those impeccably formed ice cubes that both chill your drinks and preserve your seafood? LA ICE MACHINE offers commercial ice machines for rent, and their experts possess a wealth of knowledge regarding the science of ice machines.

In this blog, we will delve into the captivating realm of commercial ice production, simplifying the fundamentals for our readers.

The Science Driving Ice Production

Commercial ice production integrates physics, thermodynamics, and engineering to craft consistent, high-quality ice cubes. Let’s break down the key steps:

Water Filtration and Purification

We initiate the process with water. Producing high-quality ice necessitates clean, filtered water. Many ice machines feature built-in water filtration systems to eliminate impurities, minerals, and contaminants. This step significantly influences the taste and clarity of the resulting ice cubes.

Freezing the Water

The subsequent step involves freezing the water. While this might seem uncomplicated, commercial ice machines employ a controlled procedure to freeze water uniformly and rapidly. Swift freezing prevents the formation of large ice crystals, which could lead to cloudy ice. Contemporary ice machines employ diverse methods, such as evaporator plates or freezing tubes, to facilitate efficient freezing.

Harvesting the Ice

Once the water is frozen, the ice must be harvested. This entails separating the ice from the freezing surface. In certain machines, hot gas is employed to release the ice from the evaporator plates, while others use mechanical devices to dislodge the ice cubes. This step guarantees the clean and consistent release of ice cubes from the freezing surface.

Storing and Dispensing

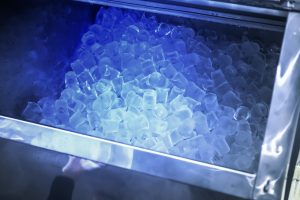

Following the harvest, the ice is stored in a bin designed to maintain its coldness and prevent melting. Certain bins have features like insulation and agitation systems to uphold ice quality. The ice is dispensed into containers or glasses for various applications when needed.

Varieties of Commercial Ice

Not all ice types are identical. Different types of ice are produced in commercial ice machines, each tailored for specific purposes:

- Cubed Ice:This represents the most prevalent ice type, commonly utilized for general cooling and beverage service.

- Crushed Ice:Ideal for blended drinks and cocktails, crushed ice offers expanded surface area, resulting in quicker cooling and more even mixing.

- Nugget Ice:Sometimes dubbed “chewable ice,” nugget ice is soft and chewable, making it a favorite for fountain drinks and healthcare applications.

- Flake Ice:Flake ice is frequently employed in food displays and seafood preservation due to its malleable nature.

For those seeking commercial ice machine rental services, LA ICE MACHINE has all your needs covered. Our ice machine rental solutions in Los Angeles encompass ice machines, bins or dispensers, and water filters – all offered at one convenient fixed price. Discover more about our offerings for commercial ice machine rental programs.